Otto Schumacher: Entrepreneurial Engineer

by David F Radcliffe

What many remember as the Knox-Schlapp factory on the corner of Graham Street and Esplanade East in the shadow of the former gasometer was originally the Schumacher Mill Furnishing Works. The entrepreneurial Otto Schumacher erected this facility in stages over three decades. Its facades provided a billboard proudly promoting the many products made there and engineering services his company offered – flour mills, grain cleaning and grinding machinery, labor saving conveying and elevating machinery, and complete foodstuff plants.

Born in Germany in 1858, Otto Charles Schumacher emigrated with his family to America when he was nine. They settled in Akron, Ohio where his uncle Ferdinand Schumacher had risen from modest beginnings to become the “Oatmeal King”, a pioneer in popularising cereal as a staple of the American breakfast table and founder of the Quaker Oats company. Young Otto apprenticed as a millwright in one of Ferdinand’s mills. In 1885, he married Lizzie Hudson in Salinas, California and a few weeks later the newly-weds sailed from San Francisco to Adelaide sponsored by John Dunn, a prominent South Australian miller, wheat merchant and philanthropist.

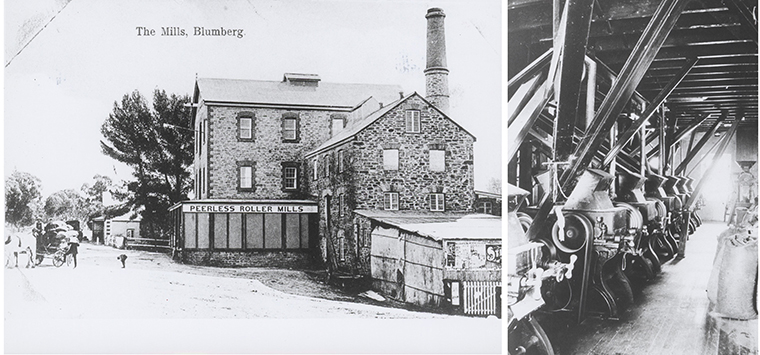

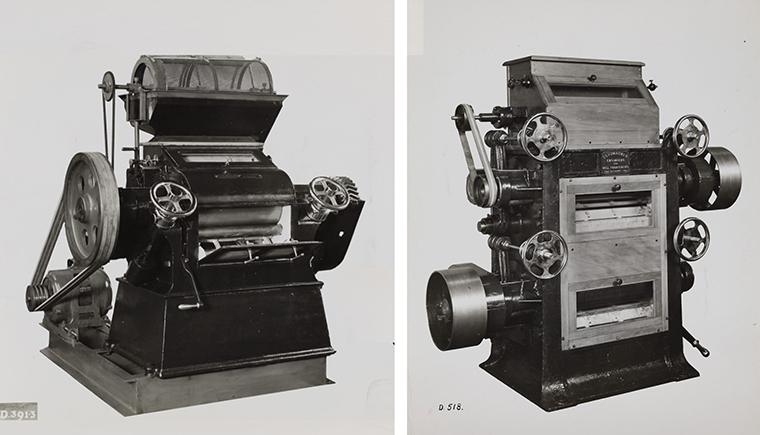

Using the knowledge and expertise of twenty-seven year old Schumacher, John Dunn & Co built the first roller mill in South Australia. In Europe and America the making of flour was transitioning from small family run mills using traditional grinding wheels powered by water or wind to an industrial process where the flour was made by crushing the wheat through a series of steel rollers powered by steam. Australia was beginning to adopt this new technology, although the machinery was all imported.

Otto Schumacher is believed to be the first person to design and manufacture equipment in Australia to furnish steam roller mills. Initially, he imported the roller mills but soon began to make some of the ancillary equipment used in milling at his factory in Kilkenny near Adelaide. His reputation grew as a builder of flour mills, as the “architect, draftsman, engineer and millwright”.

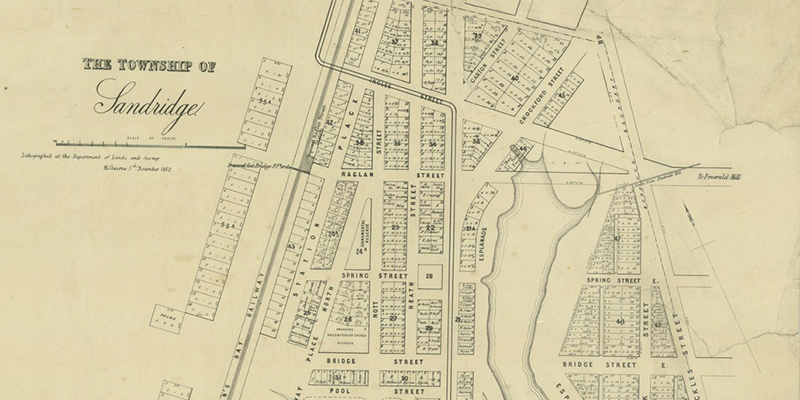

The Schumachers moved to Port Melbourne in October 1889 where Otto set about establishing a second manufacturing facility. Initially, he purchased a single Crown allotment on Esplanade East between Graham and Danks Streets running through to Johnston Street and built a small brick factory there. Over the next few years Schumacher acquired additional land either side of the factory and a blacksmiths shop was added in 1896. Although he bought land for his business, he and Lizzie and their new son Ferdinand lived in rented premises in Albert Park.

Schumacher always looked for ways to improve the design and performance of the roller mills and related equipment he manufactured. This resulted in him being awarded three patents during the 1890s. The business grew and between 1891 and 1909 Schumacher either built and furnished or refurnished at least thirty roller mills in WA, SA, Victoria, Queensland, Tasmania, NSW and New Zealand. By 1900, he had closed the Adelaide factory and all manufacturing moved to Port Melbourne.

With the development of the ‘safety bicycle’ in the late 1880s, cycling took off in Australia and Otto Schumacher embraced the craze as a business opportunity. He trademarked the name Empire Cycles Works Melbourne and manufactured his first Empire bicycle at the Port Melbourne factory in 1896 where they had a cycling track for learners.[i]Towards the end of that year, Otto opened the Schumacher Cycle Agency in Adelaide. However, Schumacher’s brief foray into bicycle manufacture ended in 1901 when he sold the Empire trademark and manufacturing rights. His attention moved to the new “must have” personal mobility device, the automobile. Schumacher was one of the fifty-five founding members of the Automobile Club of Victoria (now RACV) formed in December 1903 and he took part in the inaugural club run from Princes Bridge to Aspendale Park in February 1904.[ii] His cycle shop in Adelaide became the Schumacher Cycle and Motor Agency with exclusive rights for Humber motor cars. He sold the agency in 1909.

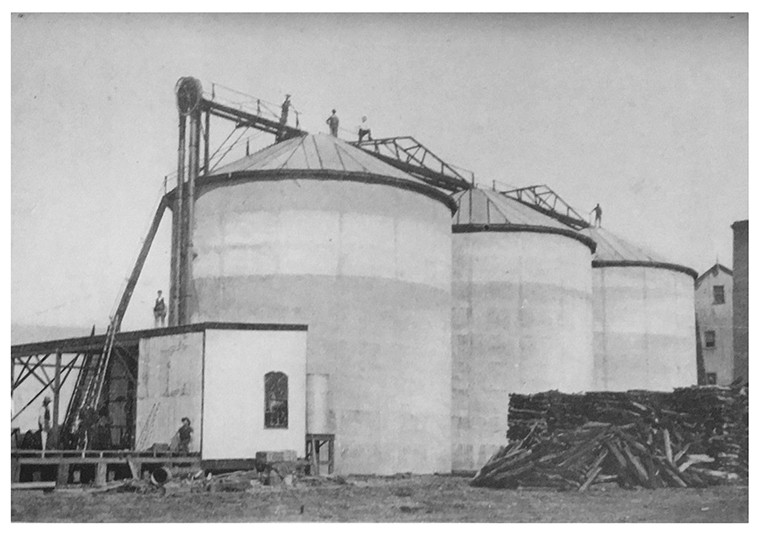

From the early 1900s, Schumacher began to diversify the range of products he made at Port Melbourne and services they offered beyond just erecting and furnishing flour mills. In 1908, he built what is believed to be the first reinforced concrete grain silos in Victoria, and possibly Australia.[iii] Designed by John Monash, these four storey high silos at the Wimmera Flour Milling Company at Rupanyup dramatically reduced handling costs and wastage associated with the traditional method of stacking bags of grain at a mill.

Schumacher’s business was incorporated as the Schumacher Mill Furnishing Works Pty Ltd in 1910. During this decade, innovation in both products and processes continued apace. In 1913, they expanded their foundry by introducing crucible steel production. In 1915, Schumacher was awarded a patent for “improvements in the separation of granular substances”. This innovation was the basis for the seed grading and cleaning machine they introduced the following year.

While Schumacher continued to make machinery for flour mills and supplied whole plants for making self-rising flour, he also adapted the milling machinery for oatmeal and sugar as well as for milling barley at maltsters and brewers. The business also began to make machinery for grinding, sifting, mixing, packing, elevating, and conveying that had application across a diverse range of industries. They imported standard items such as electric motors and worm gearboxes. Such elements were then incorporated within an overall system they designed and built for a particular customer.

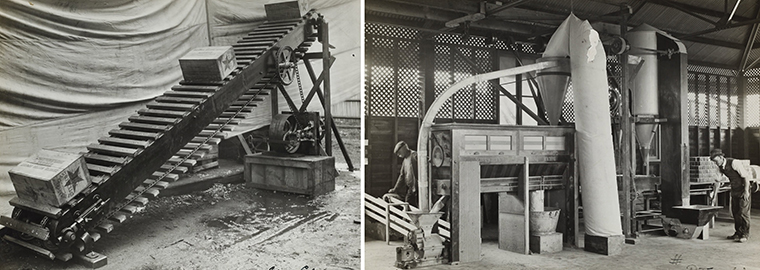

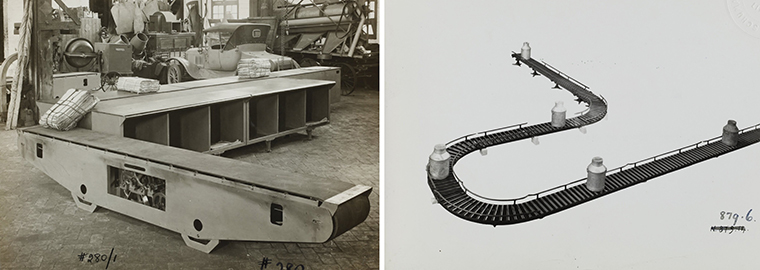

Their roller conveyor systems were used in butter factories, wholesale grocers, confectioners, bottle manufacturers and merchants, shipping companies, laundries, fruit packing sheds, orchardists, cement manufacturers, dairies, tile and brick manufacturers, boot making factories, and cordial makers. These systems included an automatic tallying device to record the number of articles passing along the conveyor.[iv] They used the expanse of their factory floor to prototype and test complete layouts for customers.

Progressively, the company developed specialised powered conveyor belts and chain driven elevators for sacks, cartons, barrels, and suchlike. Their portable inclined belt conveyor was adapted to suit builders, contractors, road makers, and was capable of handling coal, coke, ashes, soil, and similar materials. They even made a trench digger based on their inclined belt conveyor technology.

But even as their business shifted its focus to materials handling and processing in factories, Schumacher continued to supply equipment to farmers. The basic seed grader was developed into an integrated cleaner, grader, dry pickler and bagger. They made a gravity roller conveyor for moving sacks of chaff on farms and a roller conveyor entry ramp for sheep dips. For farms and factories, they supplied augers for conveying granular materials horizontally or elevating them and bucket conveyors for vertical rises. All this time Schumacher was still making roller mills.

The wide variety of products they developed through the depression years of the 1930s reflected the need to be adaptable and supply whatever type of equipment was in demand. Two of the more unusual examples were a complete blood and bone fertilizer plant (1937)and a 4-ton travelling crane (1938). During the Second World War, Schumacher won numerous government tenders to provide gravity roller conveyors to the Departments of Army, Munitions and Supply while continuing to promote their seed grader and other agricultural equipment in the rural press.

Otto Schumacher passed away at the age of 87 in January 1946. In addition to Schumacher Mill Furnishing Works Pty Ltd, he had a stake in H. Hudson & Co., a maltster in Richmond founded by his brother-in-law, and Schumacher Investments Pty Ltd. While most of his estate, valued at £140,950, went to his widow Lizzie and extended family members in America, nearly one fifth was invested as the Otto C and Elizabeth Schumacher Trust. Annual returns from this Trust supported a wide range of charities in Victoria.[v]

Ferdinand Schumacher, their only child, now headed the business. But unexpectedly, he passed away just eight months after his father, aged 56. Schumacher Mill Furnishing Works continued trading until July 1950 when the shareholders decided to voluntarily wind-up the company. All the assets were liquidated and the buildings were purchased by the engineering firm Knox-Schlapp in 1955. The factory was demolished in 1985 to make way for social housing. Lizzie Schumacher passed away in 1957, aged 91

Thanks to the diligence of the Graham Engineering Company, the last occupants of the factory, over 900 promotional photographs from the days of the Otto Schumacher Mill Furnishing Works were saved for posterity and these are now preserved by Museums Victoria. Unfortunately, we do not have any pictures of Otto and Lizzie Schumacher. They enjoyed outdoor activities and travel and had a sense of adventure. Imagine the pictures they took on their nine month trip around the world via China, Japan and America on the way to attending the Paris Exhibition of 1900.

Read about how David used historic photographs and maps to trace the development of the Otto Schumacher Mill Furnishing Works in Piecing Together the Past.

[i] ‘Cycling’, Standard (Port Melbourne), 23 May 1896, p. 3. http://nla.gov.au/nla.news-article165318679

[ii] ‘Automobile Club’ Age (Melbourne) 22 February 1904, p. 6. http://nla.gov.au/nla.news-article197230794

[iii] ‘Four thousand ton silos’ Farmer and Settler (Sydney), 11 September 1908, p. 10. http://nla.gov.au/nla.news-article115959861

[iv] ‘Mill Furnishing Works’, Herald (Melbourne), 22 July 1930, p. 30. http://nla.gov.au/nla.news-article242804024

[v] ‘Charities benefit from £140,950 estate’, Argus (Melbourne), 16 August 1946, p. 18. http://nla.gov.au/nla.news-article22315588